|

|

On the most important:

|

Science reporting session

|

Abstracts 2011

Abstracts 2012

Abstracts 2013

Abstracts 2014

|

He main directions of development of hydrogen energy (review)

Hydrogen energy: storage and transportation of hydrogen (review)

|

Monograph.

Basic problem of hydrogen energy.

|

|

|

|

|

Hydrogen-sorption carbonic nanomaterials

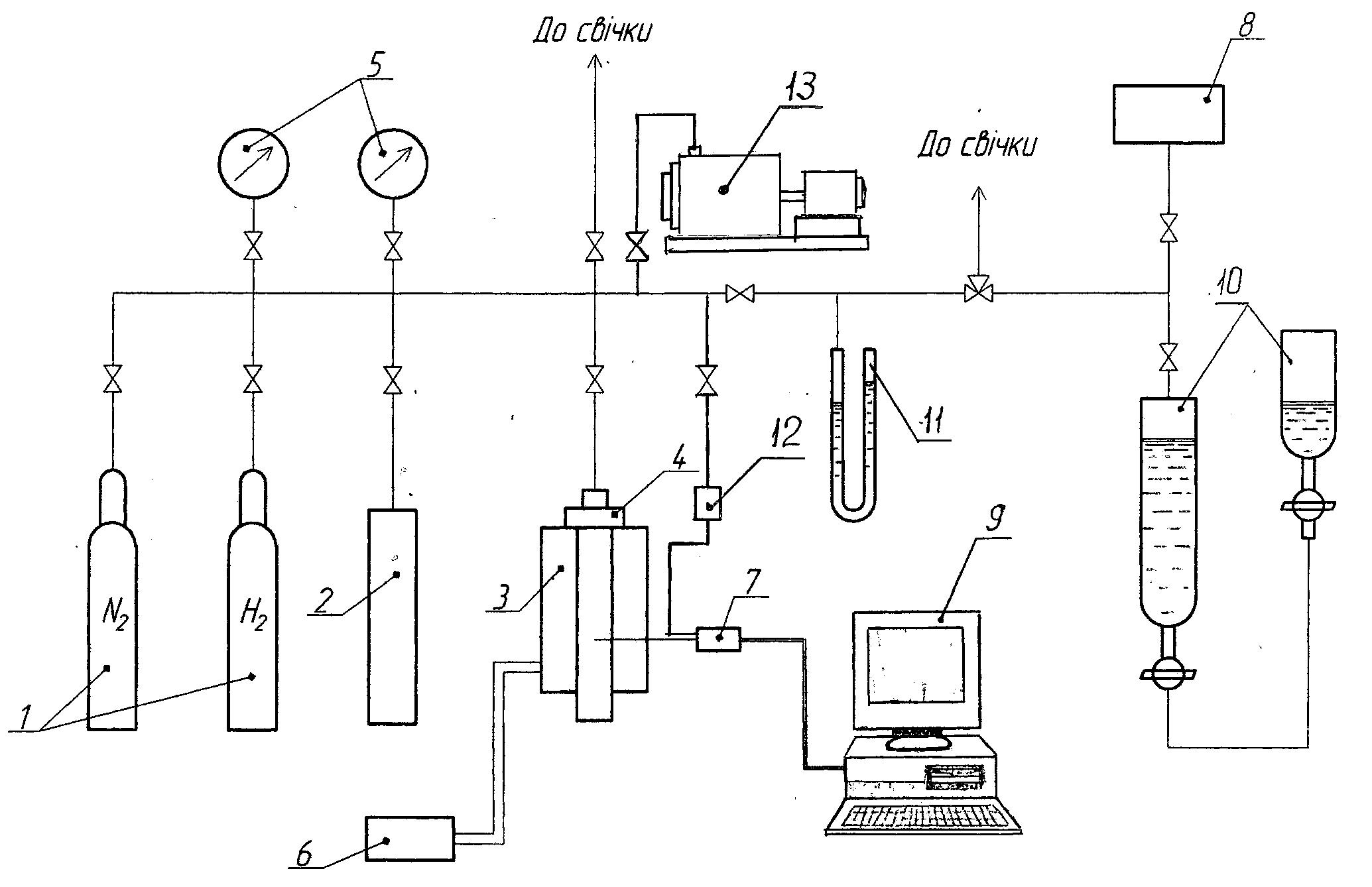

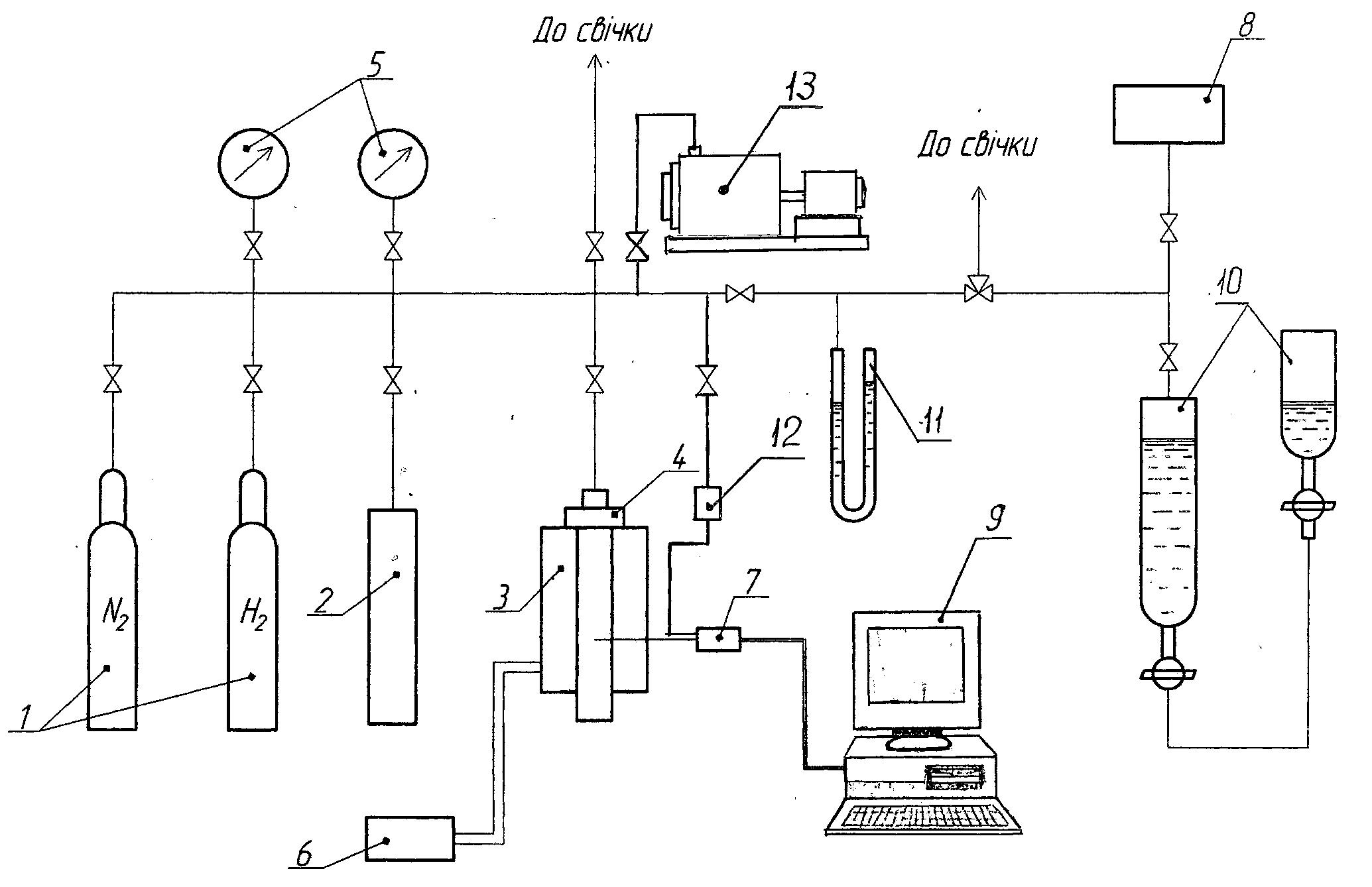

Scheme of upgraded laboratory facility for study the properties of carbon nanosorbents (CNS), process parameters and development of absorption-desorption technology suitable for industrial use:

1 – cylinder; 2 – calibrated volume ; 3 – furnace;

4 – container; 5 – pressure gauges;

6 – heating control unit; 7 – ADC;

8 – chromatograph; 9 - PC;

10 – volume H2 measurement device;

11 – pressure indicator; 12- pressure sensor ;

13- gas chromatograph.

|

Fields of application

Probable use of CNS and their production technology with significantly reduced consumption of resources for compact storage of hydrogen in hydrogen energetics.

Short Description

Technologies of carbon nanosorbents :

(а) carbon nanotubes (CNT ) – by deposition from gas phase which is product of air conversion of natural gas,

(b) termohrafenit (TRH ) - by thermal shock of oxidized carbon materials and

(в) ( c) technologies of hydrogen sorption-desorption processes using the methods of enhancement of the capacity of the obtained nanomaterials.

Expected properties

The optimal technological parameters of carbon nanosorbents production, of hydrogen sorption-desorption processes and its compact storage in containers that are under development, suitable for mass industrial use. Understanding the mechanisms of formation and increase the adsorption capacity of carbon nanomaterials.

Advantages

Advantages of chemical deposition of CNT from gas phase methods and reception of TEG by thermal shock: relatively low energy capacity, using cheap carbon materials, the possibility of creating an industrial high-yielding production , the relative simplicity of equipment and the lack of need for thorough purification of the resulting product.

Competitors

«Energy Systems Division»,

«Argonne National Laboratory»,

Argonne, Illinois, USA;

Department of Mechanical and Industrial Engineering, University of Illinois at Chicago, Illinois, USA;

Department of Energy Efficiency Research, Korea Institute of Energy Research, Daejeon, Korea.

Stage of development

(a) CNT: optimal parameters studied and effective technology for carbon nanotubes developed, which allowed to obtain sorbent sufficiently high purity and uniform quality; block of preparation and purification system for gas containing carbon are developed, the effect of form and heat treatment of catalytic surface on CNT production process are researched;

(b) TRH: plant for the production of sorbent is modernized, namely: applied two burner system for heating of oxidized initial graphite where one burner acts as a feeder feedstock. This has improved the conditions for thermal shock, which in turn increased the specific installation productivity and improved nano-layered structure of TRH (reduced bulk weight and harmful sulfur contents);

( c) laboratory setting: equipped with additional blocks of gas analytical and vacuum equipment, pressure sensors, valves with higher density to in-depth study of the processes of sorption-desorption nanosorbent samples;

research of processes at high settings is continued.

Intellectual property

EV Stratyvnov, AP Kozhan, BI Bondarenko. Mode of thermoexpanded graphite production

Pat. 99,875 Ukr., IPC (2011) S01V 31/04.

Contact Information

Executor: Gas Institute of NAS of Ukraine

Project № 28 "Fundamental Principles and processes of carbon hydrogen-sorption nanomaterials production for hydrogen energy"

Contact:

Academician of NAS of Ukraine,

Boris Bondarenko

Е-mail: bbikiev@gmail.com

|