|

|

On the most important:

|

Science reporting session

|

Abstracts 2011

Abstracts 2012

Abstracts 2013

Abstracts 2014

|

He main directions of development of hydrogen energy (review)

Hydrogen energy: storage and transportation of hydrogen (review)

|

Monograph.

Basic problem of hydrogen energy.

|

|

|

|

|

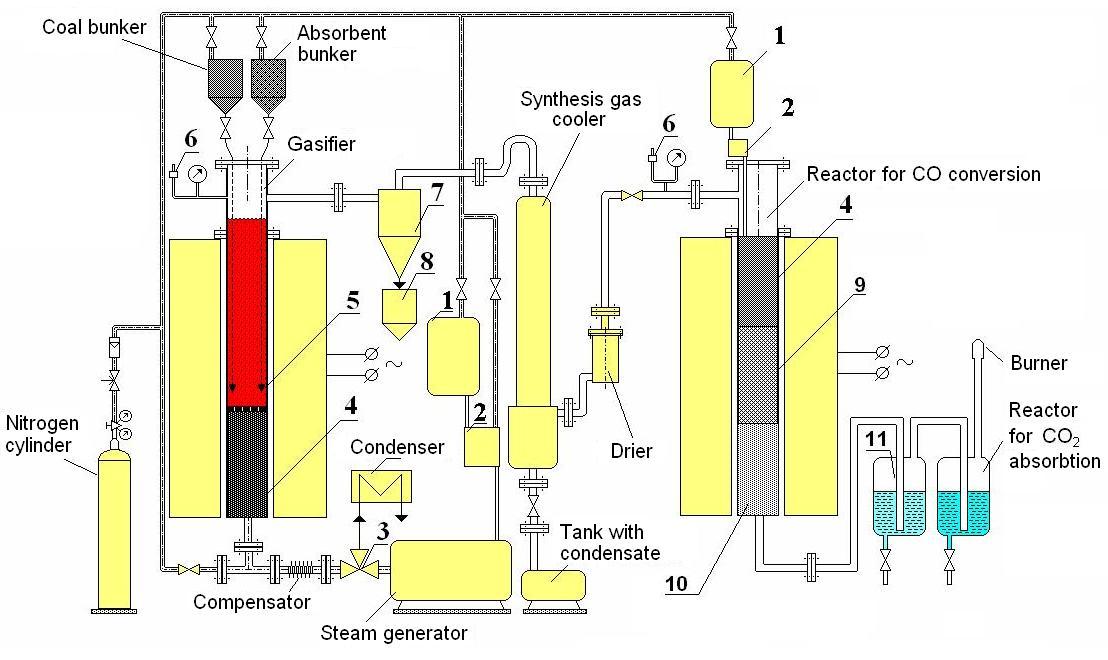

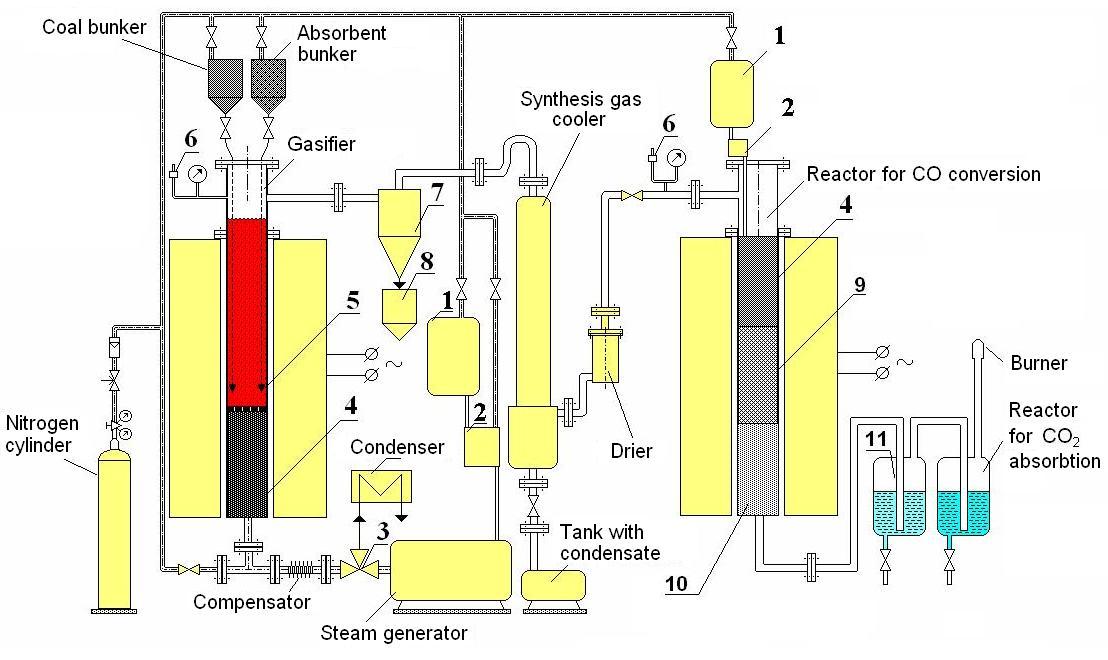

Installation for generation of hydrogen from Ukrainian coal

Installation circuit

The installation consists of main equipment: bunkers with coal and absorbent, gasifier, steam generator, synthesis gas cooler, tank with condensate, drier, reactor for CO conversion, reactor for low-temperature absorption of СО2, and burner.

Feeders 2 fed water from tanks 1 into the steam generator and the reactor for CO conversion.

Steam is fed from steam generator to the ceramic bed 4 in the gasifier through the three-way valve 3.

The steam heated into the ceramic bed is fed into the reaction zone 5 of the gasifier.

The obtained gas through the separator 7 is fed into the synthesis gas cooler.

Unreacted solid residues are collected in the bunker 8.

The obtained gas, through the drier, is fed for heating into the ceramic bed of the reactor for CO conversion 4.

In the reactor for CO conversion, there are beds of CO conversion catalysts: medium-temperature 9 and low-temperature 10.

The obtained gas is fed into the reactor for СО2 absorption through the cooler 11.

Obtained hydrogen is combusted in the burner

Field of application

Installation for generation of hydrogen from coal is used to obtain kinetic characteristics of the interaction of different Ukrainian coals with steam with the use and without the use of catalysts, with the use and without the use of СО2 absorbents. The obtained data is used for the design of new industrial gasifiers and adaptation of existing ones based on the properties of Ukrainian coals of different degrees of metamorphism. The synthesis gas after the gasifier was used to test molten carbonate fuel cell. The new circuits of IGCC Power Plants with hydrogen production and СО2 sequestration were developed based on the obtained data.

Brief description

The technological process comprises the steps of: steam generation, synthesis gas production and capture of СО2 with absorbent in the steam gasifier, synthesis gas cooling and drying, CO conversion, rich hydrogen synthesis gas cooling and low-temperature СО2 absorption. Carbon dioxide in the system is removed in the steam gasifier and in the reactor for СО2 low-temperature removal. Hydrogen with purity of 96-98% was produced from Ukrainian bituminous and brown coals.

Expected properties

Compact design of the installation for producing hydrogen from coal with the use of cheap СО2 absorbents.

Benefits

A decrease in the cost of carbon dioxide removal due to the use of two-stage process of СО2 removal.

An increase in energy efficiency due to the direct removal of СО2

Business rivals

DMT, DM2, Battelle, AER

Development status

The installation is used at the Coal Energy Technology Institute of NAS of Ukraine to test different organic fuels and catalysts. Data obtained at the installation is used for the adaptation of existing industrial gasifiers to operate with Ukrainian coal.

The development of technical and economic feasibility study and conceptual design of the steam gasifier of a new type with catalytic conversion of coal and the obtained synthesis gas with СО22 removal are intended at the end of the project 15.

Intellectual property

Know how

The method for hydrogen production / Useful model patent # 60805 from 2011.06.25, Ukraine.

The catalyst of carbon monoxide conversion / Useful model patent # 60805 from 2011.06.25, Ukraine

Contact Information

Executive: Coal Energy Technology Institute (CETI) of NAS of Ukraine

Project 15. Research of the processes of hydrogen generation from Ukrainian low-grade power-generating bituminous and brown coals. Development of new solid-fuel hydrogen technologies for alternative power generation and chemical industry.

Contact person:

Dudnyk Oleksii,

Ph. D., Senior Researcher of CETI

Е-mail: aldudnik@nas.gov.ua,

aldudnik@bigmir.net

|