|

|

On the most important:

|

Science reporting session

|

Abstracts 2011

Abstracts 2012

Abstracts 2013

Abstracts 2014pace="5" align="left" class="primer" title="Abstracts 2013"/>

Abstracts 2013

|

He main directions of development of hydrogen energy (review)

Hydrogen energy: storage and transportation of hydrogen (review)

|

Monograph.

Basic problem of hydrogen energy.

|

|

|

|

|

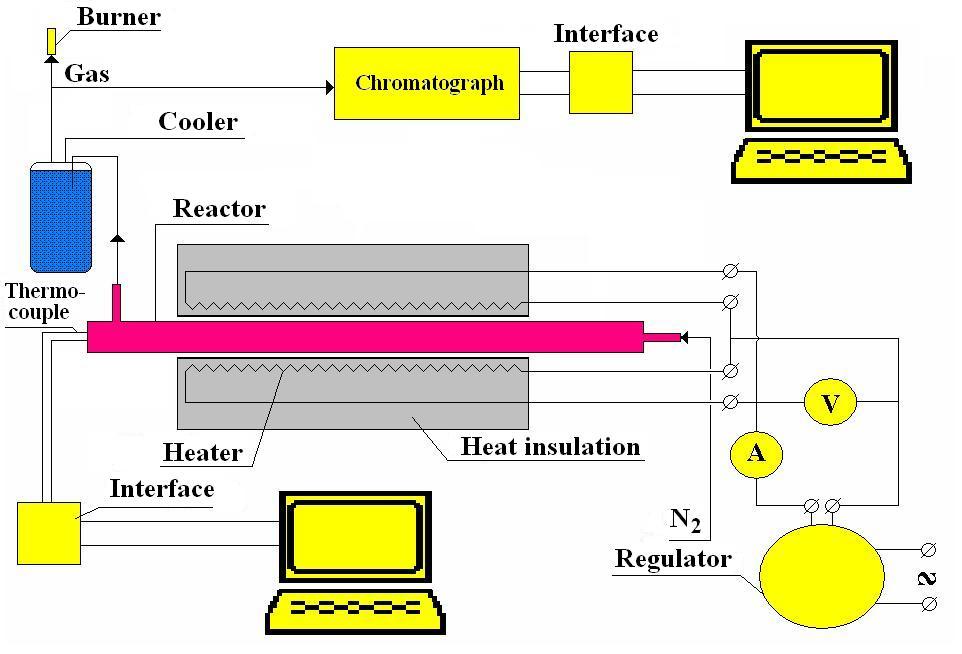

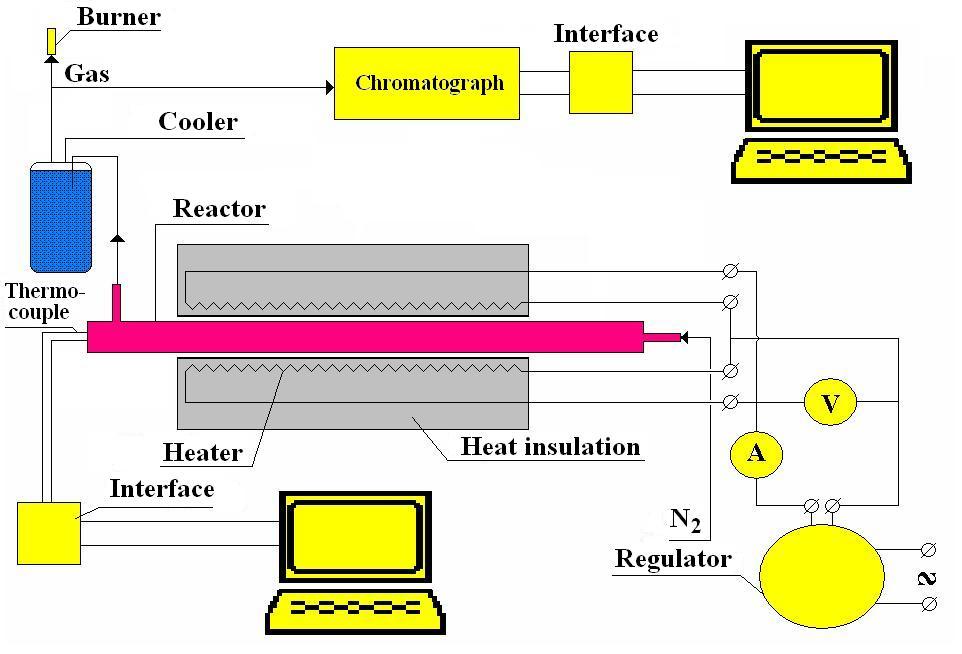

Installation for test of catalysts of biomass volatile matter conversion into hydrogen

Installation circuit

The installation consists of minichannel reactor, where biofuel and catalyst (for volatile matter conversion) are placed in special way. Biofuel carbonization and volatile matter decomposition on catalysts with heating of the minichannel reactor in the low power electric furnace are conducted by the methodology specially developed at the Coal Energy Technology Institute of NAS of Ukraine.

Field of application

At the installation, there were conducted successful tests of the porous magnetic Ni-catalyst (stabilized with SiO2) developed by the Indian Institute of Petroleum for conversion of sunflower husks volatile matter to produce the following products: gas with high content of hydrogen (up to 52 vol. %), high reactive coal (with low heat value of 23 MJ/kg), and water. The installation is used to test various biofuels and catalysts, and will be used to test new microchannel systems for conversion of gas with high content of hydrogen into hydrogen and other motor fuels.

Brief description

The technological process comprises the steps of:

- heating of biofuel and catalysts samples;

- carbonization and reforming of volatile matter without external steam supply into biofuel

bed and on the catalyst (for volatile matter conversion).

Expected properties

An increase in capacity of the installation can be achieved with an increase in the channels for carbonization and catalytic reforming of volatile matter. Improved conditions of heat exchange and mass transfer in comparison with the existing industrial installations for carbonization and gasification of biofuels are provided due to the small size of channels. The installation with minichannel reactor can be used to test different types of catalysts for volatile matter conversion with minimal power consumption.

Benefits

Simultaneous production of three useful products: gas (with heat value up to 15 MJ/nm3), high reactive coal, and water at the low-power equipment.

Low consumption of feed stock and energy.

Business rivals

-

Diversified Energy

-

Velocys

- Changing World Technologies

Development status

The installation is used at the Coal Energy Technology Institute of NAS of Ukraine to test different organic fuels and catalysts.

The creation of similar installation is planned in the Indian Institute of Petroleum.

Intellectual property

Know how

The catalyst of carbon monoxide conversion/Useful model patent # 60805 from 2011.06.25, Ukraine

Contact Information

Executive: Coal Energy Technology Institute (CETI) of NAS of Ukraine

Project # 14. Hydrogen generation by heterogeneous catalytic steam conversion of biomass and waste with chemical regeneration

Contact person:

Dudnyk Oleksii

Ph. D., Senior Researcher of CETI

Е-mail: aldudnik@nas.gov.ua,

aldudnik@bigmir.net

|