|

|

|

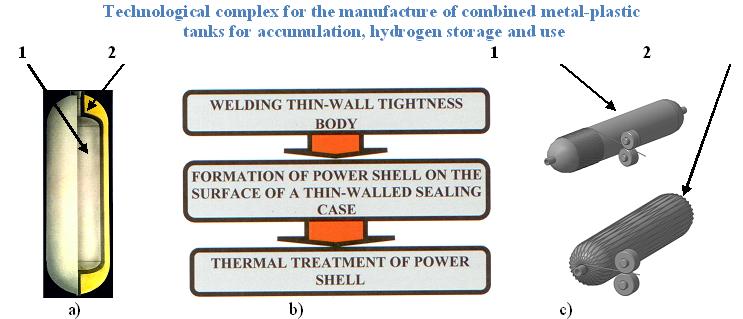

Technological complex for the manufacture of combined metal-plastic

tanks for accumulation, hydrogen storage and use

The main stages of manufacturing combined metal-plastic containers for the accumulation,

storage and use of hydrogen:

a) the design of the metal-plastic capacity: 1 - thin-walled sealed enclosure 2 - composite power shell;

b) the technological scheme of manufacturing metal-plastic containers for the accumulation, storage and use of hydrogen;

c) the stages of forming the composite power shell: 1 - winding and leveling the cylindrical part of the body; 2 - formation of the power shell.

|

Area of application

Technological complexes can be used in the manufacture of high-pressure tanks for various purposes: in hydrogen energy,

in aircraft industry, to accumulate the transportation and use of natural gas, etc. Developed combined metal-plastic containers are intended

for accumulation, storage and hydrogen use.

Brief description

The project aims to create a modern automated complex for the manufacture of light metal composite high-pressure cylinders for the accumulation,

storage and use of hydrogen in the energy, automotive, petrochemical industries. It provides for the development of technical solutions for

automating the process of manufacturing these cylinders and forming various types of power shells from high-strength fibrous materials on a

thin-walled light body. Automation of these processes will improve the quality and performance of high-pressure cylinders.

Expected results

In the process of project implementation, the following will be developed: principles for constructing automated technological complexes

with programmed control for manufacturing high-pressure cylinders, methods for improving their quality and reliability. A light thin-walled cylinder

body ensures proper tightness during hydrogen storage, and the outer shell provides resistance against destruction by internal pressure.

The high-strength fibrous material of the power shell with a low specific gravity will help reduce the overall weight of the combined tank and

increase its reliability and efficiency.

Advantages

Foreign equipment for the manufacture of high-pressure cylinders with power composite shells is worth at least 500 thousand US dollars.

According to preliminary estimates, the domestic complex will be 2-3 times cheaper and will provide a low mass and dimensional indicator (m / V)

of combined cylinders.

Competitor

Production of equipment for the manufacture of high-pressure combined cylinders:

the company X-Winder (Europe),

the company «Hurgo» (USA),

the International Joint Stock Chinese Company «Honkong Tien» (China),

the engineering center «Stankomposite» (Russia).

The capacity of tanks for accumulation, storage and use of hydrogen:

«ECD Ovonics» (USA),

«HERA Hydrogen Storage Systems» (Canada),

«Dynetek» (Canada),

«Millennium Cell» (USA),

«Euro India Cylinders Ltd».

Project development

The design of lightweight metal-plastic cylinders for the accumulation, storage, transportation and use

of hydrogen, with a welded metal body reinforced composite material. However, Ukraine does not produce equipment for the production of

lightweight combined cylinders, and foreign equipment is too expensive, which in itself hampers the development of hydrogen energy and

especially this manifest în transport.

Intellectual property

Process for the preparation of hydrogen. Ukrainian Patent number 60806, published 25.06.2011, Bulletin No 12

Catalyst for hydrogen preparation by steam reforming of ethanol. Ukrainian Patent number 115288, published 10.04.2017, Bulletin No 7

Contact information

The Paton Electric Welding Institute, National Academy of Sciences of Ukraine

Project 10 «Development of a complex for the manufacture of light metal composite high-pressure cylinders for the accumulation,

storage and use of hydrogen»

Project leader:

Savitsky Mihailo M.

Savitsky Mihailo M.

project leader

doctor of Technical Sciences

senior staff scientist

Tel. +38 044

200-17-39;

+38 044 205-23-76;

+38 044 205-23-21

Å-mail: sam@ðàton.kiev.ua

Å-mail: sam961@i.ua

Å-mail: sam961@ukr.net

|

|

Savitsky Mihailo M.

Savitsky Mihailo M.